Betel

Connecting ideas and product development to the world

September 27, 2022

This time, Ishimura, our overseas expansion promoter, visited Betel, a development-oriented manufacturing company, and spoke with its representative director, Junichi Suzuki.

Overview of the business:

Ishimura:First of all, could you tell us about your company's business overview?

CEO Junichi Suzuki

Suzuki:Our predecessor (current president) started assembling electronic components in Ishioka City in 1973. For a while, we mainly worked on jobs for major electrical manufacturers, but we then transitioned to the assembly of precision parts, utilizing the assembly technology we had cultivated. We then expanded our business domain to include plastic injection molding, mold making, and so on. Although we still maintain transactions with major electrical manufacturers, we also handle in-house developed products and have shifted our main focus to developing plastic products for medical and dental use, equipped with clean rooms. The three businesses we are currently focusing on are 1) OEM production of electrical materials and interior parts, 2) medical, dental, and caregiving (oral healthcare) products, and 3) thermal property measurement and analysis solutions.

Ishimura:So you've gradually changed your business model to keep up with the times?

Suzuki:Yes, that's right. The biggest turning point was about 20 years ago when our predecessor had a strong desire to do "something new" and we introduced Si technology by knocking on the door of the National Institute of Advanced Industrial Science and Technology in Tsukuba City, and developed our own "thermal microscope" product.

Ishimura:What is a "thermal microscope"?

Thermal Microscope TM

Suzuki:A thermal microscope, also known as a "thermal property microscope" in Japanese, is a device that measures thermal conductivity, thermal diffusivity, and thermal penetration by applying laser light to an object. The basic patent is owned by the National Institute of Advanced Industrial Science and Technology, and we participated in joint research and co-wrote academic papers with them. By using this device, it is possible to evaluate the thermal properties of thin films in extremely small areas that could not be measured before. Although our main target users were major metal and ceramic manufacturers in Japan who develop thin films for tools and optical devices, for example, we only sell a few units per year, so it has been a low-altitude business.

Ishimura:What was the reason for not selling?

Suzuki:I think the reason why "Thermal Microscope" did not sell was that its scope of use was too narrow. So, to overcome this situation, we jointly developed with the National Institute of Advanced Industrial Science and Technology a device called "Thermo Wave Analyzer", which has a wider range of objects that can be measured than the "Thermal Microscope". This device is used for simulation measurements of the process of heat diffusion, for example, when a smartphone is in operation, it generates a considerable amount of heat. When heat is generated, the processing power of the smartphone drops, so it is necessary to efficiently dissipate the heat. This device is used for measuring the thin film materials that dissipate heat when manufacturers develop them. This product has sold quite well in terms of quantity, as its usage has expanded compared to before, and electronic communication devices such as smartphones have dramatically become widespread. That is why it continues to sell to this day.

Ishimura:About 20 years ago, there were not many electronic communication devices like smartphones that had large heat generation problems. The predecessor who focused on heat conduction measurement technology was amazing.

Suzuki:The predecessor thought that measuring instruments would be essential in various fields in the future. He thought that the demand for measuring instruments would be firm. Therefore, our thermal property measurement business is currently handled by our in-house Hudson Research Institute. Considering that this measurement business accounts for a significant part of our main business, I am simply amazed at the predecessor's foresight.

Ishimura:What is the company's biggest selling point?

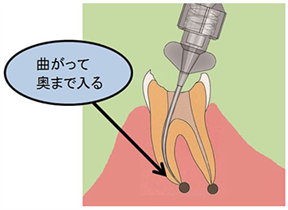

「luler rock type」Plastic tip

Suzuki:It is still our development capabilities. We have various capabilities such as mold making and injection molding, so our strength is that we can realize designs, drawings, and prototypes according to customer requests. Of course, we also handle jobs of processing parts from designs and materials received from major electrical manufacturers, but I think that is possible because we have development capabilities. For example, regarding plastic parts for medical use that our company is working on, we received a request from a medical device manufacturer who happened to find out about our technical information on our website, and that was the beginning of the trial production. Just after that, the Lehman shock happened, but despite the recession, sales of medical plastic parts in Japan's medical field not only did not decrease but increased steadily. So, I felt that there was a significant demand in the medical field and expanded our transactions with the medical industry.

Ishimura:So if a company has developed capabilities, various jobs come flying in, right?

Suzuki:Yes. That's why our company has "The origin of management is in development" as our philosophy, and we create things that Japan and the world need, such as medical and dental plastic products, as well as measurement devices for thermal properties.

Previous article Back to list Next articles